“Get Your Fix†Part 2 of 10: YORK® YLAA

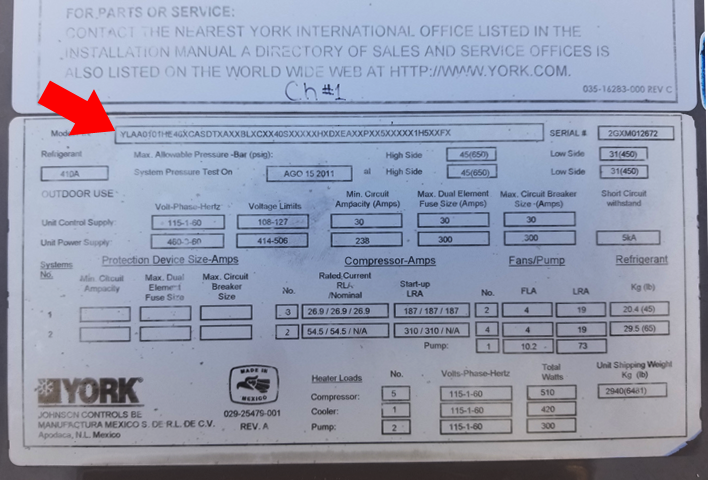

We're back with part two of our series on the top ten commercial OEM condenser coils that have faced challenges during service over the last decade. Coming in at number two is the York® YLAA series, a model that has consistently been a source of frustration for contractors and end-users alike. As we move forward in our countdown of coil issues, we’ve arrived at the YORK® YLAA chiller—a model that has become synonymous with operational problems, particularly when it comes to the durability of its MCHX condenser coils. It's a reality that we receive numerous calls every week from contractors and end users seeking solutions for leaks and other issues related to the original microchannel coil on the YORK YLAA chiller. In general, we notice that customers are dissatisfied with the durability of this OEM model, which has negatively impacted York’s reputation. While York did provide the option for both microchannel coils and copper tube coils, it’s rare to encounter this unit equipped with the higher-grade copper tubes. The Common Culprits The majority of YLAA units we come across are the Style B models, which are manufactured with microchannel condenser coils in both the standard and high-efficiency versions. Wondering how to determine whether you're dealing with a standard or high-efficiency unit? Simply check the model number. For instance, the 'S' in YLAA0700SE indicates a standard unit, whereas the 'H' in YLAA0156HE signifies a high-efficiency unit. A helpful tip: if you see a "ZE" in the model number, like YLAA0080ZE, then the unit originally came with copper tube coils. So, What’s the Solution? #ChangetheChannel Switching from microchannel to copper tubes in the YORK® YLAA chiller will significantly enhance reliability and ease of servicing while maintaining the original OEM efficiency. It’s crucial to remember that when upgrading from microchannel to copper tubes, you must complete the refrigerant circuit and increase the refrigerant charge using the sub-cooling method. This means that if your YLAA chiller has a leaking coil but that coil is part of a circuit with four coils total, you’ll need to replace all four coils. Depending on the tonnage, YLAA units can have anywhere from 4 to 12 coils. A York YLAA unit before the microchannel conversion. The same York YLAA unit with a Blygold® coating after converting the microchannel to copper tubes. If you're considering replacing only one coil, we recommend reaching out to York directly to purchase an MCHX coil. At Nationwide Coils, we don't perform partial replacements because this approach is essentially a temporary fix and won’t resolve the recurring issues associated with the York YLAA unit. Though the YORK YLAA chiller is one of the more frequently upgraded units we handle, we can perform a microchannel conversion for virtually any make or model. The Nationwide Coils Blog is a commercial HVAC blog written by industry HVAC experts with nearly two decades of hands-on experience. We provide insightful commentary on commercial HVAC products and services, and we invite you to contact us anytime. Mix Bed Resin,Mixed Bed Ion Exchange Resin,Edm Resin,Mixed Bed Resin,Wire Edm Resin Henan Comcess Industry Co., Ltd. , https://www.comcessresins.com“Get Your Fix†Part 2 of 10: YORK® YLAA