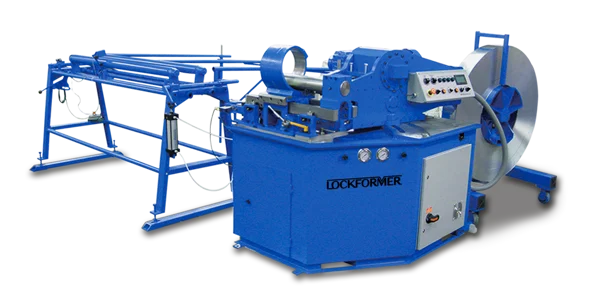

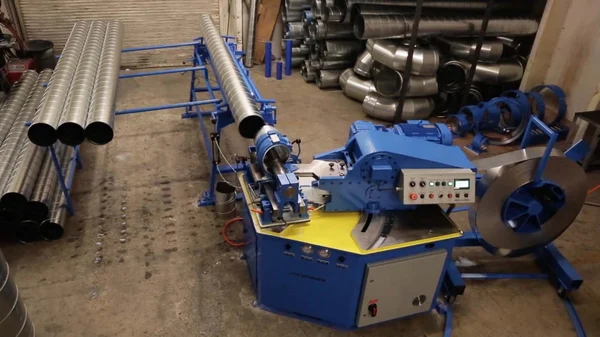

Maximize Your ROI with the Lockformer Spiral Tube Former 2.0

High Speed Capacity Heavy Gauge Capacity 16-28 gauge (0.016 – 0.065â€) galv. steel 14 gauge (0.066 – 0.079â€) galv. steel 20-28 gauge (0.016 – 0.040â€) stainless steel 18 gauge (0.041 – 0.050â€) stainless steel Speeds up to 344 FPM Speeds up to 287 FPM

The driving device is an external structure, which is composed of driving plate, motor, reducer, and coupling. Advanced mechanism configuration, small impact, stable and reliable operation. The connection with the cage adopts flexible cushioning. Which simplify the structure and ensure the meshing accuracy of the gears and racks, making the construction hoist run and brake more stable. Between the cage and the drive device, the anti-broken shaft protection device ensures the safety of the equipment during operation.

Electric control system: The electric control system of this equipment is professionally designed and produced

â‘ The shell of the electric control box is made of stainless steel plate, after many professional processes, it has good corrosion resistance and long service life;

â‘¡The electrical components are all domestic (or foreign) well-known brands, with stable performance and reliable quality;

â‘¢The connection and installation of electrical components are professional, with firm connections and strong anti-vibration ability; multi-strand copper wires are used between the components, and the wire end terminals are pressed firmly, the current conduction effect is good, which can exert the component performance effectively;

â‘£The function of automatic leveling and floor calling is realized.

The safety device is complete and reliable. Equipped with: loading-capacity Limiter, upper and lower limit switch, lower deceleration switch, upper and lower limit switch, anti-falling safety device, single door interlocking limit switch of cage, double door interlocking limit switch of cage, cage maintenance door limit switch, guardrail door interlocking limit switch, cage buffer spring, four-in-one protector, etc. The Fangyuan construction hoist has a unique anti-reverse design of rail joint bolts, which effectively avoids major elevator accidents and ensures the construction of the lift work safety and the performance reliable .

Curved Construction Elevator,Multi Function Construction Lift Hoist,Slope Angle 15 Building Hoist,High Security Curved Construction Hoist Fangyuan Group Co.,Ltd. , https://www.fygcorp.com Designed to combine the best features of previous models, the Spiral Tube Former 2.0 offers both high-speed and heavy-gauge capabilities, making it versatile for a wide range of applications. Whether you're working with galvanized steel or stainless steel, this machine delivers consistent performance across different material thicknesses.

Designed to combine the best features of previous models, the Spiral Tube Former 2.0 offers both high-speed and heavy-gauge capabilities, making it versatile for a wide range of applications. Whether you're working with galvanized steel or stainless steel, this machine delivers consistent performance across different material thicknesses.

Equipped with a frequency drive electric motor, the Spiral Tube Former 2.0 operates quietly while delivering smooth, high-quality results. Its compact, fully automatic design makes it ideal for tight spaces without compromising on speed or power. The innovative Spiral Smart Technologyâ„¢ (SST), integrated with MestekNet Control Software, provides precise length-cutting, efficient diagnostics, and simplified operator setup.

The on-the-fly slitting device ensures clean, quiet cuts with no burrs or sparks, perfect for tubes with a minimum diameter of 4†and a maximum thickness of 20 gauge. Its trailer-mountable design allows for easy transport to job sites, while compatibility with various CAM programs ensures seamless integration into existing workflows.

One of the standout features of the Lockformer Spiral Tube Former 2.0 is its ability to produce consistently strong seams. With advanced seam welding technology, it ensures uniform, durable connections that prevent air leakage and improve overall duct performance.

Maintaining dimensional accuracy is also a key strength of this machine. Its precise control system allows operators to adjust diameter and pitch with high accuracy, ensuring that every tube meets exact specifications. This reduces waste and improves material utilization, making the manufacturing process more efficient.

The streamlined workflow and intuitive controls make it easy for operators to switch between different tube sizes and configurations quickly. Combined with high-speed production, this helps fabricators meet tight deadlines without sacrificing quality.

Safety and comfort for operators are also top priorities. The machine includes built-in safety mechanisms and an ergonomic design that minimizes fatigue and enhances productivity over long shifts.

In summary, the Lockformer Spiral Tube Former 2.0 is a powerful tool that brings innovation, precision, and reliability to HVAC duct fabrication. From improved seam quality to enhanced workflow and operator safety, it addresses the most common challenges in the industry. Whether you're a small shop or a large-scale manufacturer, this machine is designed to help you produce high-quality spiral tubes efficiently and effectively.

In summary, the Lockformer Spiral Tube Former 2.0 is a powerful tool that brings innovation, precision, and reliability to HVAC duct fabrication. From improved seam quality to enhanced workflow and operator safety, it addresses the most common challenges in the industry. Whether you're a small shop or a large-scale manufacturer, this machine is designed to help you produce high-quality spiral tubes efficiently and effectively.