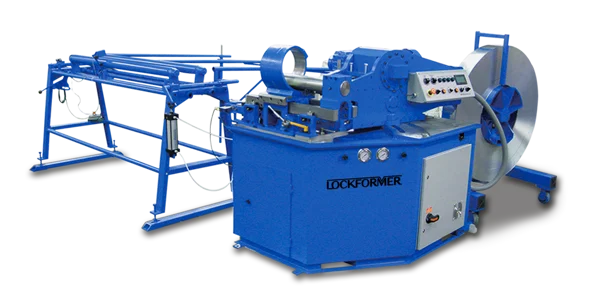

Maximize Your ROI with the Lockformer Spiral Tube Former 2.0

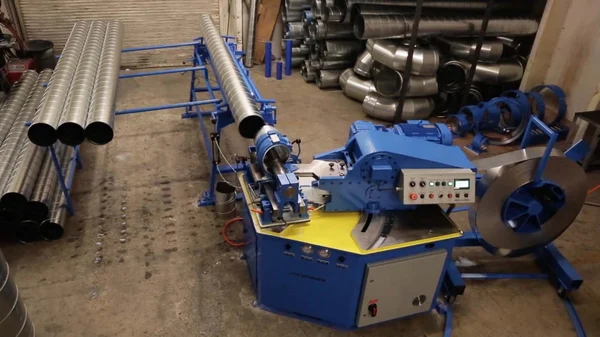

16-28 gauge (0.016 – 0.065â€) galv. steel 14 gauge (0.066 – 0.079â€) galv. steel 20-28 gauge (0.016 – 0.040â€) stainless steel 18 gauge (0.041 – 0.050â€) stainless steel Speeds up to 344 FPM Speeds up to 287 FPM Walking Pile Drilling Machinery

Pile driver for construction site,the features showing as below:

1.Excellent performance, fast lifting, large lifting weight.

4.The hole wall drilled by pile drilling has good stability, complete hole cleaning after hole completion and fast construction progress.

Walking Pile Drilling Machinery,Construction Equipment Pile Driver,Hydraulic Hammer Pile Driver,Highway Guardrail Pile Driver Fangyuan Group Co.,Ltd. , https://www.fygcorp.com

Lockformer Spiral Tube Former 2.0 Features

Combining the best of previous models, the Spiral Tube Former 2.0 offers both high-speed performance and heavy-gauge capabilities, making it one of the most versatile machines in the market. Here’s a closer look at its key features:

High Speed Capacity

Heavy Gauge Capacity

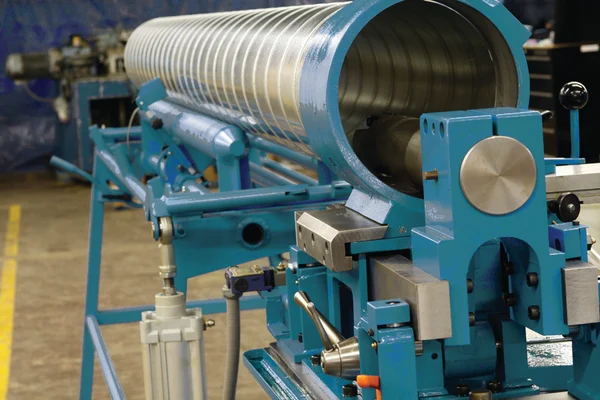

Precise Seam Quality

Ensuring consistent seam quality is essential for maintaining the structural integrity and air-tightness of spiral ducts. The Lockformer Spiral Tube Former 2.0 delivers superior seam welding, resulting in strong, uniform seams that reduce the risk of leaks and improve overall duct performance.

Dimensional Accuracy

Maintaining exact dimensions throughout the manufacturing process is crucial for proper fitting and installation. The Spiral Tube Former 2.0 features a highly accurate control system that allows operators to adjust diameter, pitch, and other parameters with precision. This level of control reduces material waste and ensures every tube meets exact specifications.

Streamlined Workflow

The Spiral Tube Former 2.0 boosts productivity by simplifying workflows and reducing setup times. With an intuitive interface and easy-to-use controls, operators can quickly switch between different tube sizes and configurations. Its high-speed capabilities help fabricators meet tight deadlines without sacrificing quality.

Operator Safety and Comfort

Safety and comfort are top priorities in the design of the Lockformer Spiral Tube Former 2.0. It includes built-in safety features and ergonomic elements to create a safer and more comfortable working environment. This not only minimizes the risk of accidents but also helps reduce operator fatigue, leading to long-term efficiency and sustainability.

In conclusion, the Lockformer Spiral Tube Former 2.0 redefines what's possible in HVAC duct fabrication. From precise seam welding to accurate dimensions, streamlined workflows, and enhanced operator safety, this machine provides a complete solution to common challenges in the industry. Whether you're a seasoned fabricator or just starting out, the Spiral Tube Former 2.0 is a powerful tool that helps you produce high-quality spiral tubes efficiently and reliably.

In conclusion, the Lockformer Spiral Tube Former 2.0 redefines what's possible in HVAC duct fabrication. From precise seam welding to accurate dimensions, streamlined workflows, and enhanced operator safety, this machine provides a complete solution to common challenges in the industry. Whether you're a seasoned fabricator or just starting out, the Spiral Tube Former 2.0 is a powerful tool that helps you produce high-quality spiral tubes efficiently and reliably.

2.Ensure that all indexes of pile foundation verticality, hole position, hole depth and sedimentation thickness meet the requirements of construction specifications.

3.The unique sealing structure design of the power head can effectively prevent the cement slurry from entering the reducer case and prolong the service life of the power head.

5.Having high cost performance, wide application scope and high social and economic benefits;

6.The Caterpillar Pile Drilling Machinery characteristic of stabilization, credibility, speediness and high capability which makes the Pile Drilling is favored.