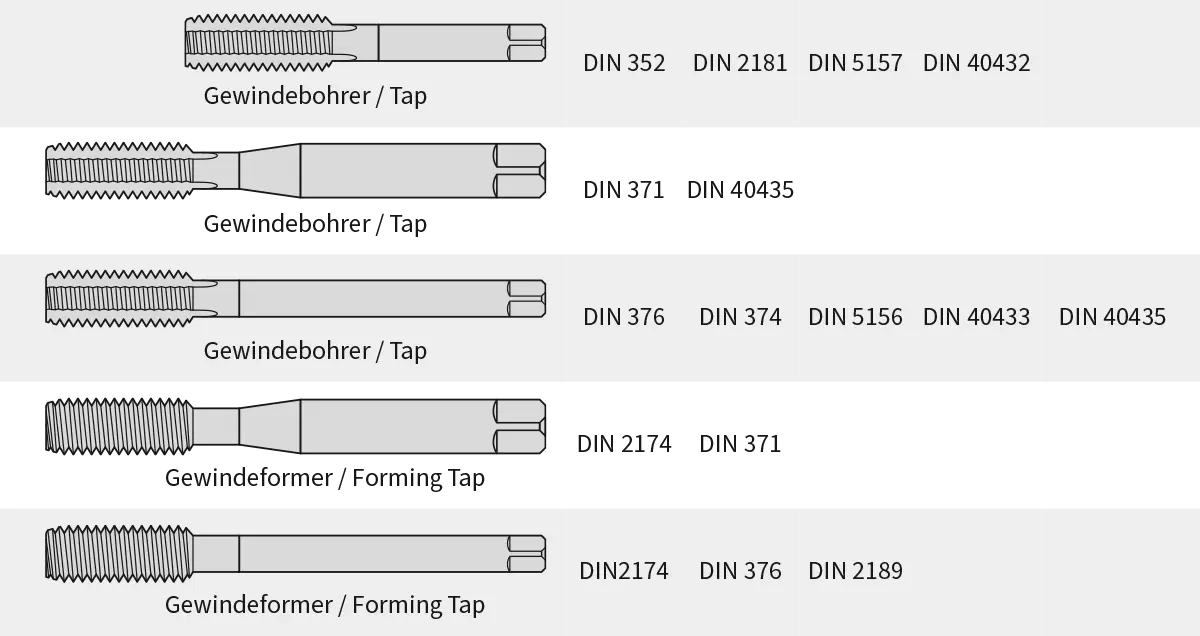

Types of taps

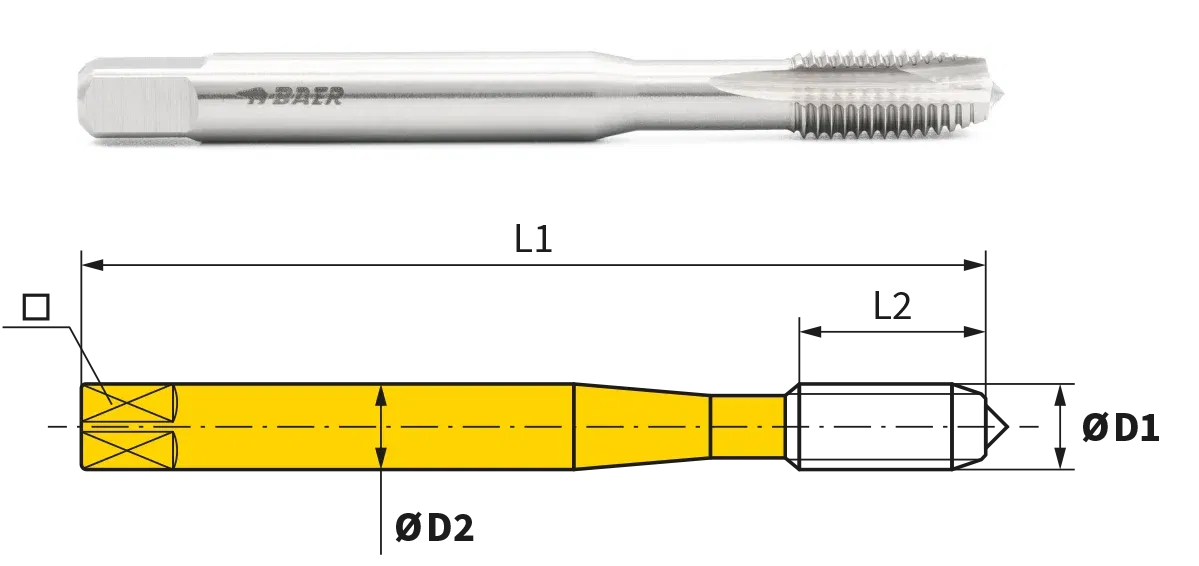

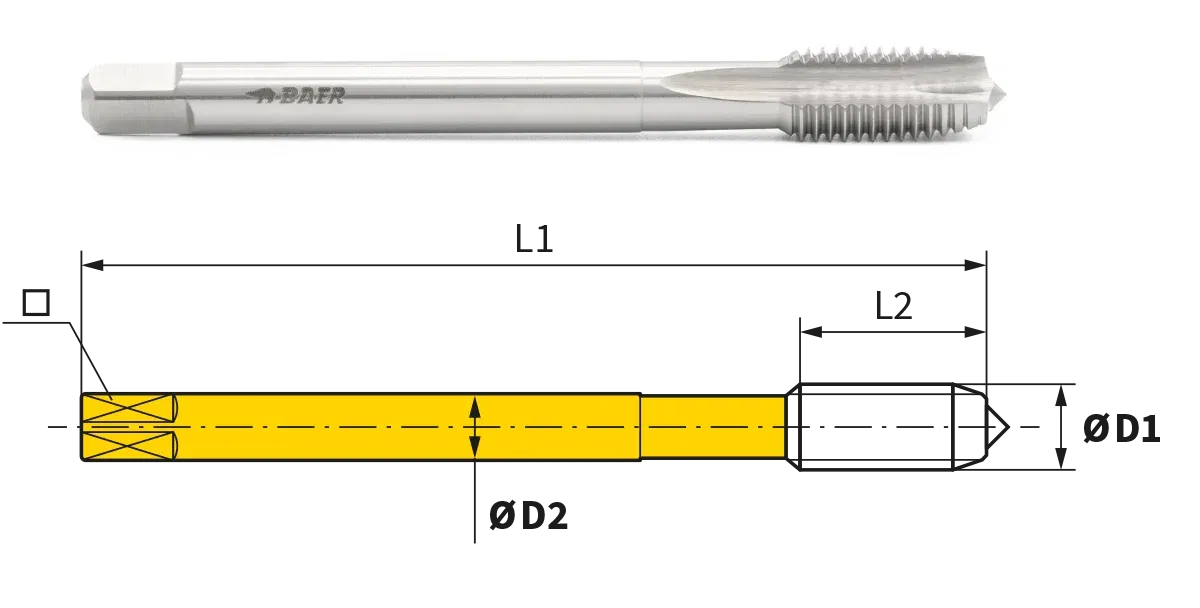

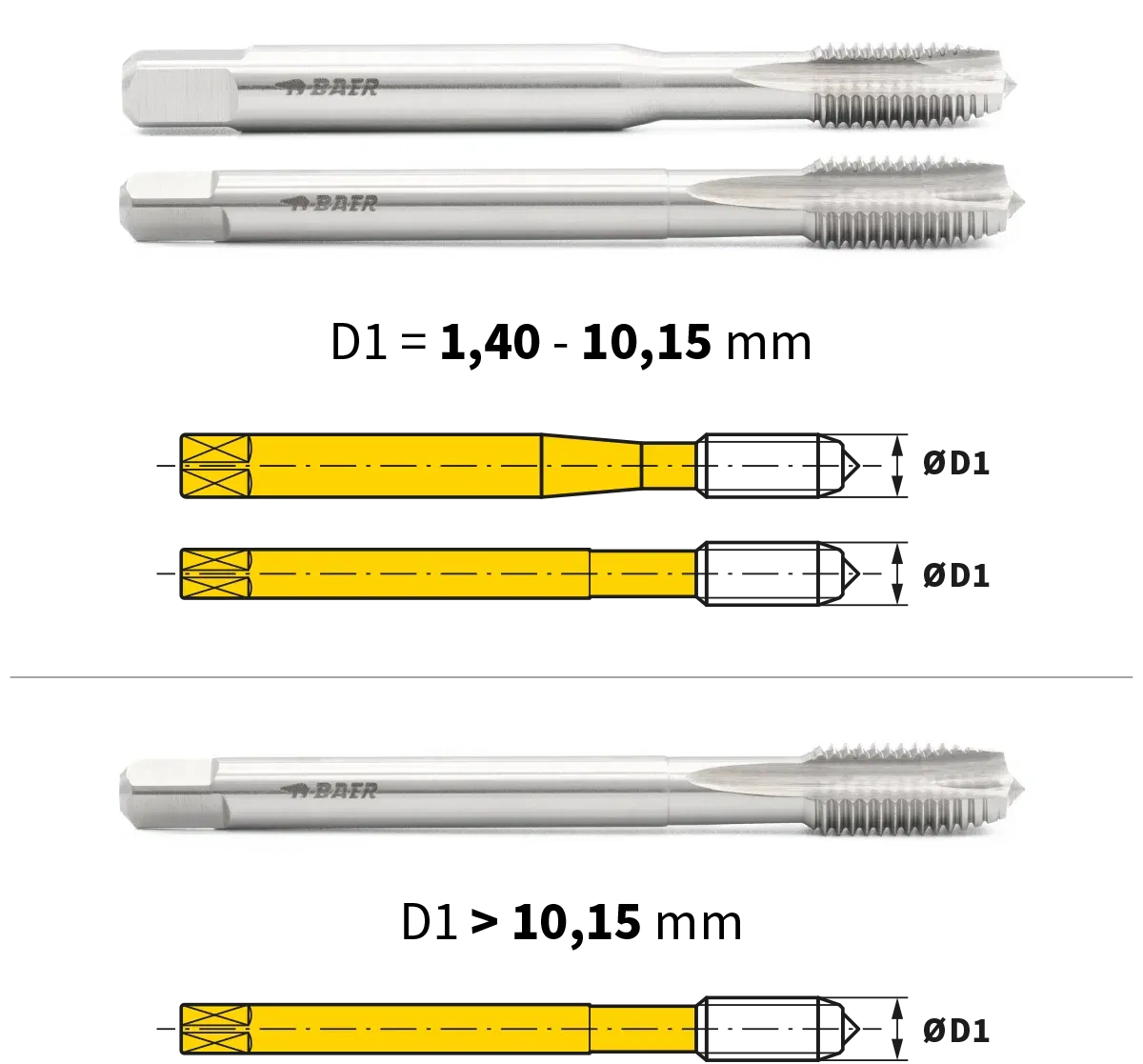

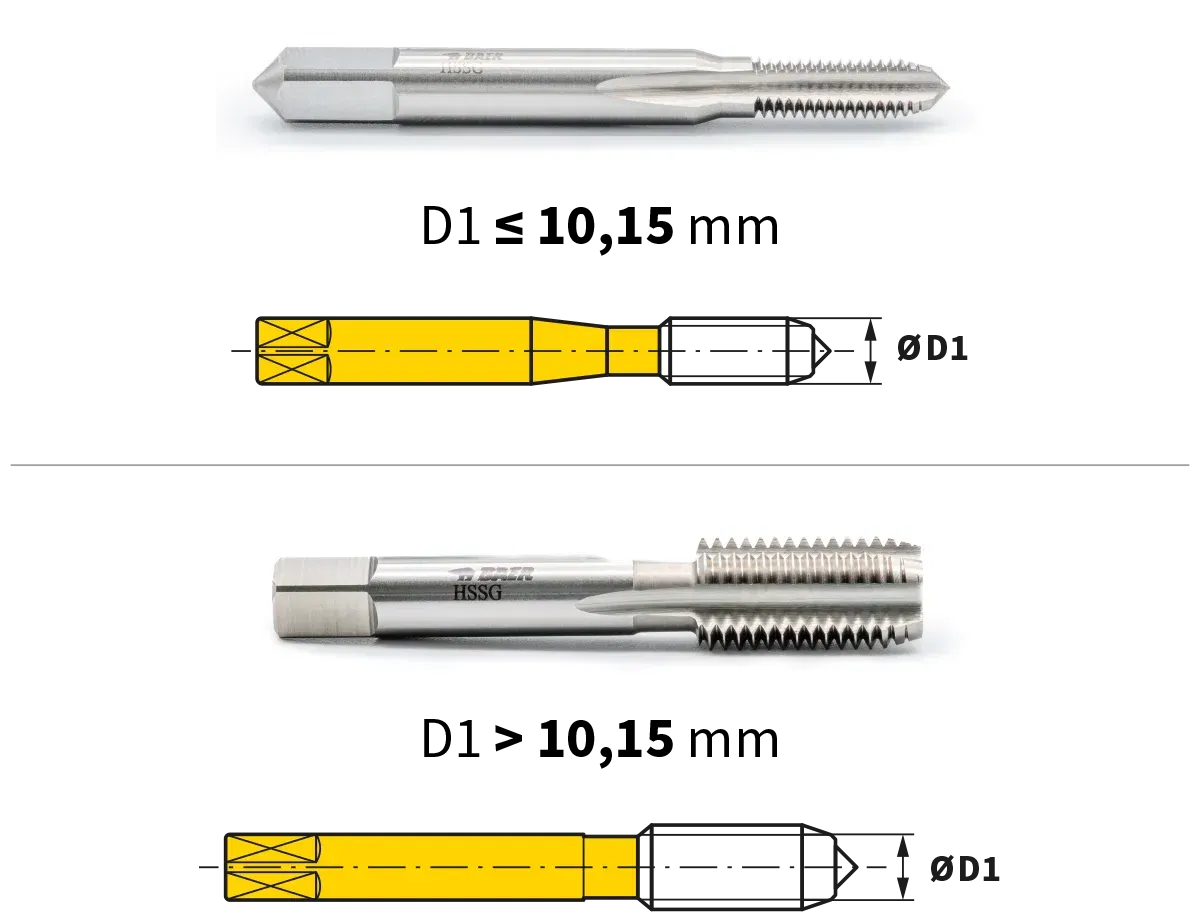

Not only is the profile of taps specified down to the last detail, the body and in particular the shank are also subject to precise guidelines. In this context, we speak of the designs, which we would like to introduce to you here. The common basis for almost all the standards that we will look at below is the DIN 10 standard, which specifies the tolerances for square shanks of cylindrical shanks for rotating tools, and the DIN 2197 standard, which contains the technical delivery conditions for ground high-speed steel taps. The DIN 2184 standard specifies the main dimensions for taps and thread taps, which can be used to produce threads with nominal diameters between 0.90 mm and 113 mm. The other standards, which we will discuss below, refer to these dimensions in accordance with DIN 2184. This standard therefore forms the basis for the other tap designs. The DIN 2184 standard is divided into two parts, DIN 2184-1 and DIN 2184-2. An important feature of tap designs is the shank shape. It is also repeatedly referred to in the other standards. The design used for the shank depends on the nominal diameter of the tap. The shank shape is determined based on the pitch, the number of threads and the total length or maximum thread length of the tap. Two variants can be distinguished: With a reinforced shank, the shank diameter d2 is larger than the nominal diameter d1. A reinforced shank is used for small thread sizes. As the shank is larger than the actual thread, the achievable thread depth is limited by this feature. With a stepped shank, the shank diameter d2 is smaller than or the same size as the nominal diameter d1. Taps with a stepped shank are also referred to as overflow taps. Part 1 of the DIN 2184 standard deals with the main dimensions for long taps and thread taps. In this standard, each pitch and each nominal diameter and shank diameter is assigned an overall length or the maximum thread length. For a nominal diameter between 1.40 mm and 10.15 mm, the standard 2184-1 lists dimensions for both a reinforced shank and a stepped shank. For values below this, only a reinforced shank is provided, for nominal diameters above 10.15 mm only a stepped shank. Part 2 of the DIN 2184 standard includes the main dimensions for taps and thread taps in short design. It also contains information on the assignment of pitch, nominal diameter, shank diameter and overall length or maximum thread length. In contrast to the DIN 2184-1 standard, only one shank design is assigned to each nominal diameter: a reinforced shank up to a nominal diameter of 10.15 mm and a stepped shank for values above this. The DIN 352 standard specifies the dimensions for three-part tap sets, each with a pre-cutter, center cutter and finish cutter, and for short machine taps. All taps described are intended for the production of a metric ISO standard thread in accordance with DIN 13-1 in a nominal diameter range from M1 to M68. The shank shapes correspond to the dimensions in DIN 2184-2. The DIN 357 standard contains the dimensions for nut taps, which can be used to produce nuts with a metric ISO standard thread in accordance with DIN 13-1 from M3 to M68. The values for the shank diameter correspond to the specifications in DIN 2184-1. The DIN 371 standard refers to machine taps for cutting metric ISO standard threads according to DIN 13-1 from M1 to M10 and metric ISO fine threads according to DIN 13-2 to DIN 13-5 from M1 x 0.2 to M10 x 1.25. The shank shapes follow the dimensions in DIN 2184-1, but only the version with a reinforced shank is taken into account. The DIN 374 standard covers the dimensions for machine taps that can be used to produce ISO metric fine threads in accordance with DIN 13-2 to DIN 13-9 from M3 x 0.2 to M52 x 4. The shank shapes follow the specifications in DIN 2184-1. Taps according to DIN 374 are tools with a stepped shank, so-called overflow taps. Accordingly, only this shank variation from DIN 2184-1 is taken into account. The DIN 376 standard contains the dimensions for machine taps for the production of metric ISO standard threads according to DIN 13-1 from M1.6 to M68. The dimensions follow the specifications in DIN 2184-1, whereby only the stepped shank is taken into account as a shank variation. As in DIN 374, these are therefore overrunning drills. Standard 2182 contains the dimensions for two-piece tap sets, which consist of a pre-cutter and a finish cutter and are intended for the production of metric ISO fine threads according to DIN 13-2 to DIN 13-9 from M1 x 0.2 to M52 x 4. The dimensions comply with DIN 2184-2. The DIN 5156 standard specifies the dimensions for machine taps that can be used to produce pipe threads G 1/16 to G 2 (internal threads for connections that do not seal in the thread) and Rp 1/16 to Rp 2 (internal Whitworth pipe threads). The specifications in this standard are not suitable for machine taps for Whitworth pipe threads according to DIN 3858 (cylindrical internal thread and tapered external thread). The dimensions follow DIN 2184-1, whereby only the shank variant for overflow taps is taken into account. The DIN 5157 standard refers to two-piece tap sets, which consist of a rough tap and a finish tap and are intended for tapping pipe threads G 1/16 to G 4 and Rp 1/16 to Rp 4. The dimensions in this standard are not suitable for taps for producing Whitworth pipe threads in accordance with DIN 3858 (cylindrical internal thread and tapered external thread). The dimensions for the shank shape can be found in DIN 2184-2. Standard 40432 specifies the dimensions for two-piece tap sets consisting of a pre-cutter and a finish cutter, which can be used to produce steel armored pipe threads according to DIN 40430 in the range Pg 7 to Pg 48. The shank dimensions are based on the specifications in DIN 2184-2. Standard 40433 specifies the dimensions for machine taps that are used to produce steel armored pipe threads in accordance with DIN 40430 in the range Pg 7 to Pg 48. The dimensions are to be selected in accordance with DIN 2184-1, whereby the variation with stepped shank is to be used. These are therefore overflow taps. The DIN 40435 standard contains the dimensions for machine taps that can be used to produce holding threads EG for wire thread inserts in accordance with DIN 8140. It covers the ranges EG M2 to EG M52 for the holding thread and EG M8 × 1 to EG M48 × 3 for the fine holding thread. The dimensions correspond to the specifications of DIN 2184-1. It should be noted that the reinforced shank variation must be selected for the locating thread up to and including EC M8, and the overrunning shank for all other sizes. In addition to the DIN standards, the ISO 529 standard, which contains dimensions for short machine and hand taps, is also important. The specifications apply to taps that can be used to produce the metric ISO standard or fine thread, the ISO inch threads of the American UNC and UNF series as well as the British inch threads BSW, BSF and BA. Swing Reducer Excavator,Excavators Swing Reducer,Excavator Swing Reducers,Swing Reducer For Excavator,Excavator Swing Reducer Assembly XINGTAI ZHONGWEI ZHUOTE HYDRAULIC TECHNOLOGY CO.,LTD , https://www.zwzhtehydraulic.comGeneral plan of dimensions for taps according to DIN 2184Â

Shank shapes for taps according to DIN 2184Â

Reinforced shankÂ

Stepped shankÂ

Main dimensions for taps according to DIN 2184-1Â

Main dimensions for taps according to DIN 2184-2Â

Types of taps for metric ISO standard and fine threadsÂ

Types according to DIN 352Â

Types according to DIN 357Â

Types according to DIN 371Â

Types according to DIN 374Â

Types according to DIN 376Â

Types according to DIN 2181Â

Types of taps for pipe threadsÂ

Types according to DIN 5156Â

Types according to DIN 5157

Types of taps for steel armored pipe threads

Types according to DIN 40432Â

Types according to DIN 40433Â

Types of taps for holding threads (DIN 40435)Â

Designs for short machine and hand taps according to ISO 529

I. Product Overview

II. Complete production line

1. Material selection:

2. Precision machining:

3. Heat treatment:

4. Assembly process:

5. Quality inspection:

III. Market share

IV. Product quality

1. Strict quality control system:

2. Advanced detection equipment:

3. Professional technical team:

4. Reliable performance:

Our products include: